Products

Voir la catégorieProducts

-

Soldering paste

This product is suitable for cutting tools, jewelry, metal frames, and other products welding, settle the soldering machine temperature at range of 580 ℃ to 880 ℃, then use with high silver soldering wire, like brazing alloy, manganese, copper, steel and stainless steel can get the best welding effect. Advantages: 1. This flux has strong permeability, good diffusion, after use the workpiece surface can be smooth and easy to do next process. 2. It can be used repeatedly without caking or settling after long time storage. 3. Good ability to remove oxidation film, and its high activity can be maintained at the range of melting temperature .

- Plastic polishing paste (first...

-

Aluminum frame stripping water

This product is made by various powerful solvents according to the advanced formula and technology.It has good shedding effect for the coatings on aluminum frame surface, like acrylic, epoxy resin, polyurethane, electrophoresis paint...so it can solve the waste problem which caused by the failure painting in the production process.

-

Plastic steel stripping water

This product is made by various powerful solvents according to the advanced formula and technology.It has good shedding effect for the coatings on plastic steel surface, like acrylic, epoxy resin, polyurethane, electrophoresis paint...so it can solve the waste problem which caused by the failure painting in the production process.

- Plastic polishing paste (secon...

- Plastic polishing paste (third...

- Plastic polishing paste (final...

- Metal polishing paste (first t...

- Metal polishing paste (final t...

-

Nylon stripping water

This product is made by various powerful solvents according to the advanced formula and technology.It has good shedding effect for the coatings on nylon surface, like acrylic, epoxy resin, polyurethane, electrophoresis paint...so it can solve the waste problem which caused by the failure painting in the production process.

- Flat polishing machine

-

Double -side Grinding Machine

Double -side Grinding Machine

-

Dry & wet vortex polishing machine

Dry & wet vortex polishing machine Wet polishing using with polishing agent or shinning agent

-

soldering water

This product has been widely used in many manufacturers, which can create good benefits for manufacturers and reduce production time.The soldering water is suitable for metal materials like copper and stainless steel , have good effect to remove the oxide layer on the surface of the metal, increase the wettability and liquidity of solder, then improve the welding capacity. It is liquid, so the workpieces can easy to dip the liquid for welding.

-

Varnish oil

Varnish oil

-

Rubber triangle stone(Wet thi...

Wet third vortex polishing(fine polishing)

-

Rubber cone stone(Wet third p...

Wet third vortex polishing(fine)

-

Rubber fragment stone(Wet thi...

Wet third vortex polishing(fine polishing)

-

Rubber triangle stone(Wet sec...

Wet second vortex polishing(medium polishing)

-

Rubber cone stone(Wet second ...

Wet second vortex polishing(medium polishing)

-

Rubber fragment stone(Wet sec...

Wet second vortex polishing(medium polishing)

-

Rubber triangle stone(Wet fir...

Wet first vortex polishing(rough polishing)

-

Rubber cone stone(Wet first p...

Wet first vortex polishing(rough)

-

Rubber fragment stone(Wet fir...

Wet first vortex polishing(rough polishing)

-

Wet system vortex machine

Wet system vortex machine Wet polishing using with polishing agent or shinning agent

-

Double side grinding machine

Double side grinding machine

-

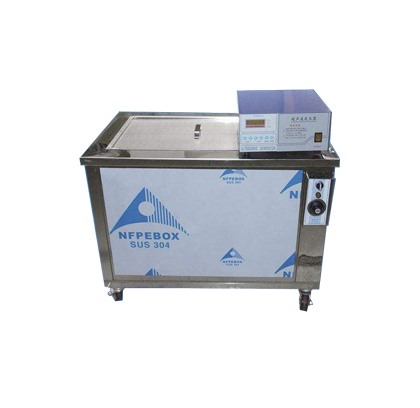

Ultrasonic cleaner

Ultrasonic cleaner Using with wax remover

- Vibration polishing machine

-

High speed centrifugal barrel ...

High speed centrifugal barrel machine

-

Vibration polishing machine (c...

Vibration polishing machine (circular motion)

-

Adjustment tumbling machine

Adjustment tumbling machine(for injection molding frame and temple) Using with special glue stone and water,without polishing agent.

-

Magnetic polishing machine

Magnetic polishing machine

-

Dry & wet vortex polishing machine

Dry & wet vortex polishing machine

-

Tumbling machine (up and down)

Tumbling machine (up and down) using for dry plastic tumbling or metal shinning tumbling

-

Tumbling machine (left and right)

Tumbling machine (left and right) using for dry plastic tumbling

-

High speed hanger barrel machine

High speed hanger barrel machine(for dry metal tumbling)

-

Nuts abrasive media cleaning m...

Nuts abrasive media cleaning machine

-

Wooden cubes cleaning machine

Wooden cubes cleaning machine

-

Metal separator

Metal separator(separating walnut chips and metal workpiece)

-

Low speed barrel machine

Low speed barrel machine

-

Shaking tumbling machine (Italy)

Shaking tumbling machine (Italy)

-

PVA wheel

PVA wheel

-

Hemp wheel

Hemp wheel

-

Nylon wheel

Nylon wheel

-

Polishing wheel (for titanium)

Polishing wheel (for titanium)

-

Cloth wheel (SFC-01)

Cloth wheel (for endpiece or bridge) SFC-01

-

String wheel

String wheel

-

Felt wheel

Felt wheel

-

Cloth wheel

Cloth wheel

-

White cloth wheel

White cloth wheel

-

Nylon wheel (for titanium)

Nylon wheel (for titanium)

-

Abrasive wheel (for titanium)

Abrasive wheel (for titanium)

- Titanium blue wax(D-36)

- Pink wax(KT-126)

- 3B white wax

- 5# Small white wax

-

Sweet potato wax

Sweet potato wax

- Yellow wax for plastic

-

Yellow wax (Super shinning)K-175

Yellow wax (Super shinning)K-175

-

Paint wax(Polishing after pai...

Paint wax(Polishing after painting)

-

Purple wax

Purple wax

-

Sand wax

Sand wax

-

Yellow wax for metal

Yellow wax for metal

- Crystal glue

- Laminated glue (Japan acetone...

- Laminated glue (common ) GP-202

-

Thinner (for rubber)

Thinner (for rubber)

-

Thinner (for CP)

Thinner (for CP)

-

Thinner (for metal)

Thinner (for metal)

-

Thinner (for nylon)

Thinner (for nylon)

- 15*15 Wooden cube

-

10*10 Wooden cube

Dry second tumbling(second rough polishing)

-

7*7 wooden bullet

Dry third tumbling(medium polishing)(mixed with 7*7 cube=1:1)

-

7*7 Wooden cube

Dry third tumbling(medium polishing)

-

Efficient stripping water

This product is made by various powerful solvents according to the advanced formula and technology.It has good shedding effect for the coatings on metal surface, like acrylic, epoxy resin, polyurethane, electrophoresis paint...so it can solve the waste problem which caused by the failure painting in the production process. (this type is more efficent and stripping fast in normal temperature)

-

Rack stripping water

This product is made by various powerful solvents according to the advanced formula and technology.It has good shedding effect for the coatings on rack surface, like acrylic, epoxy resin, polyurethane, electrophoresis paint...so it can restore the rack surface and then reuse. (It belongs to acid containing liquid and only apply to rack with no next coating)

-

Normal temperature Stripping water

This product is made by various powerful solvents according to the advanced formula and technology.It has good shedding effect for the coatings on metal surface, like acrylic, epoxy resin, polyurethane, electrophoresis paint...so it can solve the waste problem which caused by the failure painting in the production process.

-

High temperature stripping water

This product is made by various powerful solvents according to the advanced formula and technology.It has good shedding effect for the coatings on metal surface, like acrylic, epoxy resin, polyurethane, electrophoresis paint...so it can solve the waste problem which caused by the failure painting in the production process.

- Lubricating agent KT-1

- Titanium polishing paste (firs...

- Titanium polishing paste (fina...

-

Wax remover (for plastic)

This product is a kind of professional product which effectively removes all kinds of plastic workpiece surface polishing wax scale and other residue after polishing.This agent use scientific method, which made by unique and high quality surfactant. Advantages: 1. Quick and thorough wax removal, strong wetting and infiltration capacity, low proportion concentration, no corrosion and discoloration of the substrate. 2. Long lasting, environmentally friendly and durable, which can make the polished surface bright without spots and easy for washing. 3. Simple operation and long-term environmental protection.

-

Wax remover (for metal)

This product is a kind of professional product which effectively removes all kinds of metal workpiece surface polishing wax scale and other residue after polishing.This agent use scientific method, which made by unique and high quality surfactant. Advantages: 1. Quick and thorough wax removal, strong wetting and infiltration capacity, low proportion concentration, no corrosion and discoloration of the substrate. 2. Long lasting, environmentally friendly and durable, which can make the polished surface bright without spots and easy for washing. 3. Simple operation and long-term environmental protection. It is widely used in stainless steel tableware, watch,glasses, gold and silver jewelry, water heating sanitary ware, and other metal technology processing industries.

- Polishing agent

-

Shinning agent

本品是不含硫、磷、强酸、添加剂的水溶性光泽剂。没有毒性、氧化性和燃性,且有良好的去油污,防锈和清洗功能。快速使原有金属制品超过原来的光泽,污水排放符合环保要求。广泛适用于超硬材料、硬质合金等硬质材料如铅锡合金,铜,锌合金,不锈钢,铝合金,铁等金属零部件的研磨出光,可大大提高研磨出光效率。同时形成高质量的加工表面,为后续工序打好基础。

-

5*5 Wooden cube

Dry final tumbling(fine polishing)

- Oxide remover (for cupronickel )

- Oxide remover (for stainless s...

- Oxide remover (for titanium )

-

Anti-acidification agent

This product is suitable for steel, copper alloy, stainless steel, and other metal, which can form a layer of white protect film on the workpiece's surface, in order to prevent oxidation during high temperature welding. Use this chemical protective treatment can recovery luster of metal.This product contains anti-oxidant elements in it which can protect the original color of the metal, and can be directly plated or sprayed after cleaning.