- Contact person:Captain

- Mobile Phone:13322988291

- Q Q:

- Tel:0755-28603021

- Fax:0755-28861003

- E-mail:Chase@klscpt.com

- Address:NO.59,Anxin Road

- Henggang Street,Longgang

- District,Shenzhen City

-

Pink wax(KT-126)

Pink wax(KT-126)

-

Yellow wax for plastic

Yellow wax for plastic

-

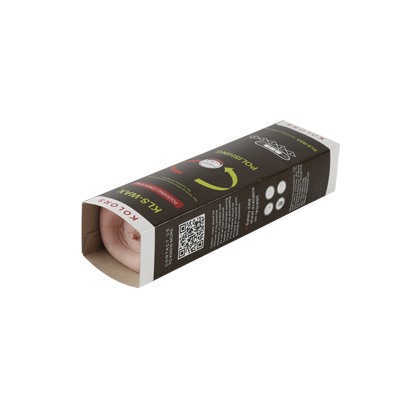

Yellow wax (Super shinning)K-175

Yellow wax (Super shinning)K-175

-

Yellow wax for metal

Yellow wax for metal

-

Dry & wet vortex polishing machine

Dry & wet vortex polishing machine Dry polishing using with AP-2 for shinning

-

High speed centrifugal barrel ...

High speed centrifugal barrel machine

Home | About | Products | News | Partner | Download | Talent recruitment | Contact | Map | Administration

Address:NO.59 ,Anxin Road, Henggang Street, Longgang District, Shenzhen City

Tel:0755-28603021 E-mail:Chase@klscpt.com Zip code:518115